Forming/Extrusion

Drop Roller

The BCH range of drop rollers is perfect for producing hard candy, toffee, and gum. Available as hand-operated or motor-driven, additional rollers can be purchased with any pattern and are interchangeable.

Capacity: Up to 1,300 LB/Hr

Features:

- Hygienic design for easy access and cleaning

- Versatile rollers which are easy to replace

- Custom-built rollers to your specifications

- Water cooled rolls option when using the motor-driven option

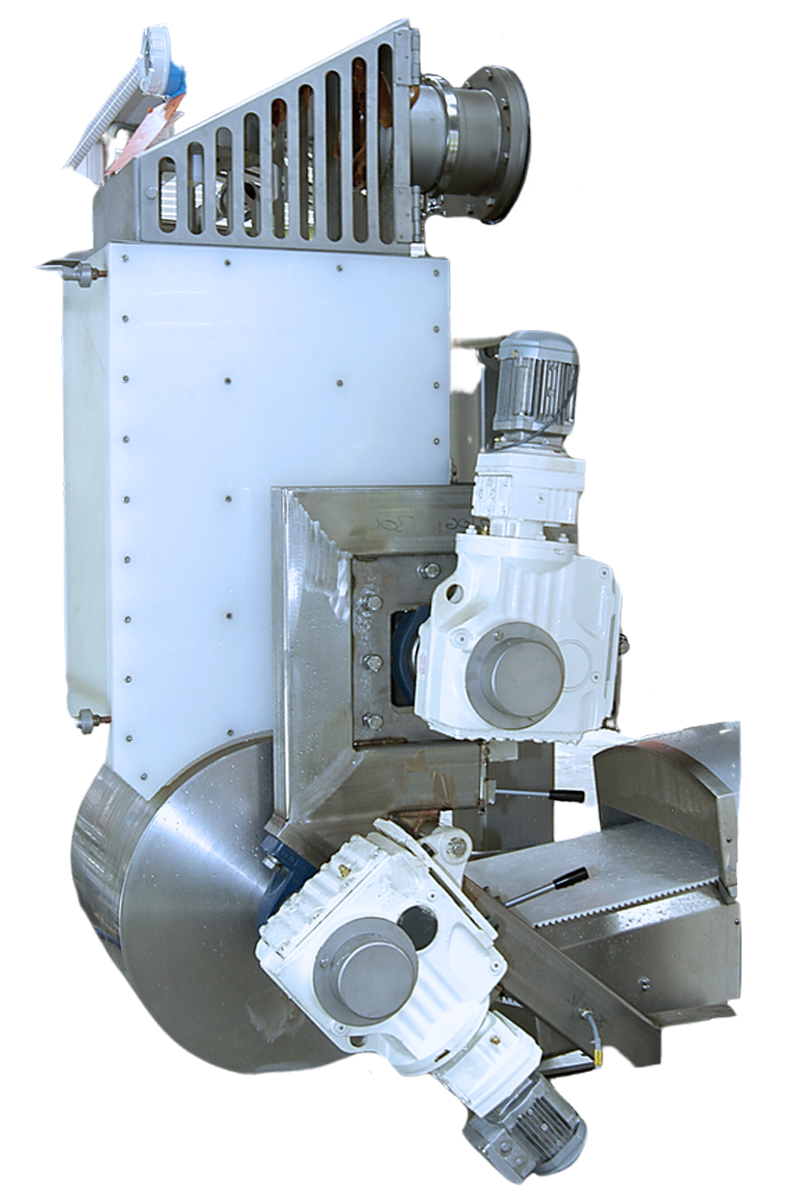

Slab Former

The BCH slab former is ideal for products such as caramel, fudge, nougat, and pastes. Constructed using stainless steel, this hygienic design can be created with different widths and thicknesses depending on the desired outcome.

Features:

- High-efficiency water cooling channels

- Variable roller gap adjustment for precise slab thickness control

- Removable scraper blades

- Temperature-controlled product inlet hopper

Our Featured Forming/Extrusion Equipment Brands

Request a Future Appointment

Forming & Extrusion Equipment Available at DC Norris North America

The extruders are manufactured with 75, 130, or 200mm diameter screws to achieve throughputs of between 110-3,300 lb/hr via a side flow die configuration. The side flow dies will extrude over widths from 300-1200mm at right angles to the screw axis. Side flow dies can be designed to extrude sheets, ropes, and twisted ropes in solid, hollow, or co-extruded form.

The side flow design provides a cost-effective, high-output system with good uniformity of product weight across the die width. This uniformity is achieved by careful design of the screw across the die mouth; regulating/throttling plates/ screws on the dies and for some products, a positive displacement pump on each rope. The extruders are usually mounted on rails to position the dies over a retracting nose piece on the BCH high-performance cooling tunnels. For die changing and cleaning, the extruders can be wheeled offline. The main barrel of the extruder is water jacketed to minimize start-up times, maximize extrusion efficiency and in the case of the twin screw mixer extruder, provide heat transfer.

The extruder is fitted with a small vacuum inlet hopper to receive licorice directly from the continuous cooker. The vacuum hopper enables the extrusion of a cooler, drier, and firmer licorice product. When fitted with a larger feed hopper, batch-fed product is possible

This type of extruder enables the mixing of colors, flavors, and acids into a cooked licorice base. Using this type of extruder, color and flavor contamination of the premix and cooking equipment is eliminated, enabling rapid color changes, minimal loss of flavor, minimal sugar inversion, and starch gel breakdown. The extruder is fitted with a screw extraction system for rapid and easy cleaning. This mixer extruder is an efficient continuous mixer for multiphase products, such as sugar paste, seeded chew syrups, and cereal bar mixes.

Suitable for any viscous product:

- Sugar paste

- Caramel

- Fudge

- Chocolate

- Nougat

- Chew

The process begins with a neutral cooked product being fed into a high-pressure, low-shear extruder. The product is split into 6 channels, each of which can be individually colored and flavored. Up to 40 ropes can be extruded onto the BCH cooling/drying tunnel each of which contains the 6 colors in equal metered proportions. The flow control of each color channel to each rope is automatic, and no manual regulation of the machine is required, leading to quick start-up and guaranteed rope weight control. Rope can be extruded in a huge variety of shapes and designs including twisted, straight, flat straps, squares, and stars.

They can also have hollow or filled centers.

- Labor-saving with quick start-up

- Unique CIP System reducing energy costs

- Flexible and fast color change