Cook Quench Chill

Cook Quench Chill Model 3000 and 4000 Range

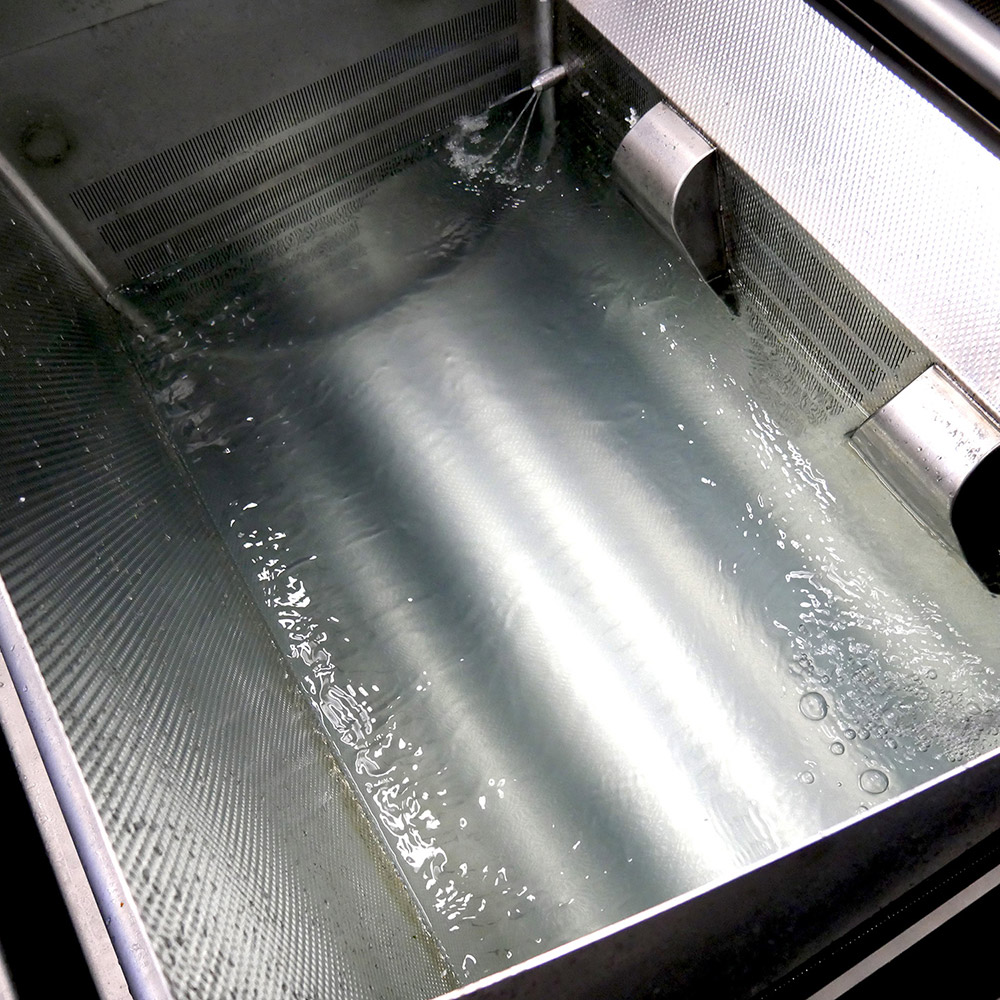

The DC Norris North America Cook Quench Chill machine is designed to automatically cook rice, vegetable and pasta products in tipping baskets using three stages. The first tank contains water which is heated up and cooks the product. Product is then transferred to the second quench tank containing cold (ambient) water to take the bulk heat out of the product, stop the cooking and refresh the product. The final tank contains chilled water and completes the cooling process. The baskets containing the product can lift and lower in the water to give a gentle agitation in each of the three stages. The final exit of product is usually into a de-watering vibrating conveyor.

All models are heated by direct steam injection and have a water overflow rim incorporated into the water tanks to prevent spillage onto the production floor and cross-contamination between high and low areas.

Options

- A new unique Wave Pump Agitation system is available, which provides the perfect agitation for ‘long’ pastas.

- De-watering

Rotary & Linear Cook Quench Chill

These systems follow the same cooking process as our original cook quench chill machine but have a smaller footprint/design to suit a more compressed factory production area.

- Available as 2, 3, 4 or 5 basket machines

- Basket Capacity Sizes – 20, 130, or 200 gallons

- Glycol Chillers

- Easy to use HMI – stores recipes

- Loading/unloading by tote bin lift or conveyor

- Food safe and hygienic components

- Distinct low risk/high care division

- Unique water heating system

COOK QUENCH CHILL ‘ADAPT’ SYSTEM

THE COOK QUENCH CHILL ‘ADAPT’ SYSTEM (OR CQC ADAPT) BRINGS A VERSATILE MODULAR DESIGN TO MANUFACTURERS WITH OPTIMIZED PERFORMANCE FEATURES.

For more than 30 years, DC Norris has manufactured cook quench chill machines that are currently installed in food production facilities around the globe. Launched in 2021, the Cook Quench Chill ‘Adapt’ System features advanced high-speed cooking technology in a modular design.

The CQC Adapt gives food manufacturers remarkable flexibility. Its modular construction allows the CQC Adapt to be installed over a high care/low-risk barrier, or as a single unit that can be expanded at any time to give a larger capacity and throughput. The CQC Adapt System modules attach together easily, simplifying installation prior to connecting to services.

CQC ‘ADAPT’ BENEFITS

- Patented Jet Heat direct steam heat system gives optimum performance with faster heat-up and cooking times

- Save water and energy with five water level options according to product and batch size

- The water holding tank has a separate weir to allow the starch to be run off during cooking, meaning less frequent water changes

- Safe to operate with fully interlocked guarding

- Product quality assured with Wave Agitation System

- Easy to clean with no external switches or wires. CIP system for internal pipework and heat exchangers. Water gun provided for manually washing baskets

COOK QUENCH CHILL ‘ADAPT’ SYSTEM FEATURES

The CQC Adapt is designed to give maximum water savings with smaller tank capacities and variable water levels to suit different batch sizes.

A Starch Removal System means the same water can be re-used for a new batch. Internal heat exchangers continuously chill and control the Quench and Chill water temperature, saving more water as it recirculates through the stainless steel heat exchangers. The heat exchangers are cleaned as part of the in-place cleaning regime, backflushing is also available.

A DC Norris-designed hydraulic tipper makes loading of the product easier and quicker, tipping directly from the floor.

The CQC Adapt has a stainless steel trough vibrating conveyor which drains water from the product before discharging into a standard tote bin or product trays.

DC Norris’s industry-standard Recipe Manager Software controls the entire Cook Quench Chill ‘Adapt’ system. Each product has its own unique cooking parameters written in to give precise repeatable times and temperatures. These are then recorded for full traceability.

Products such as pasta, rice, potatoes, and vegetables are cooked or blanched continuously at faster speeds due to the addition of two patented Jet Heat direct steam heat systems. Product quality is assured with The variable Wave Agitation System, which produces a damage-free product and prevents product clumping.