Sous Vide Cook Tanks

CT-1

A 50-gallon capacity commercial sous vide cook tank designed to fit the batch and floorspace requirements of commercial food producers.

Capacity: 50 Gallons

Features: Plug & Play, fully automated, no minimum batch size, NSF Certified

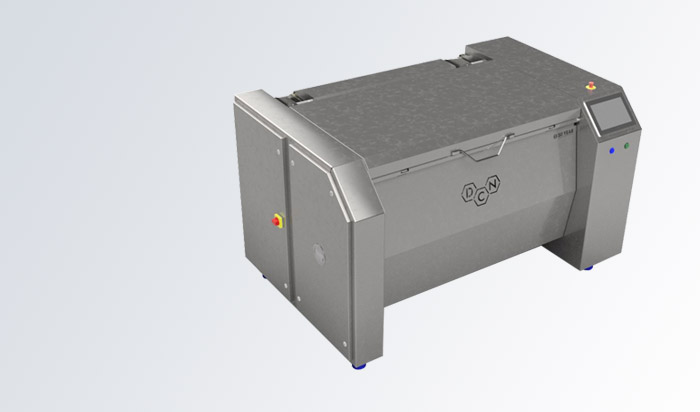

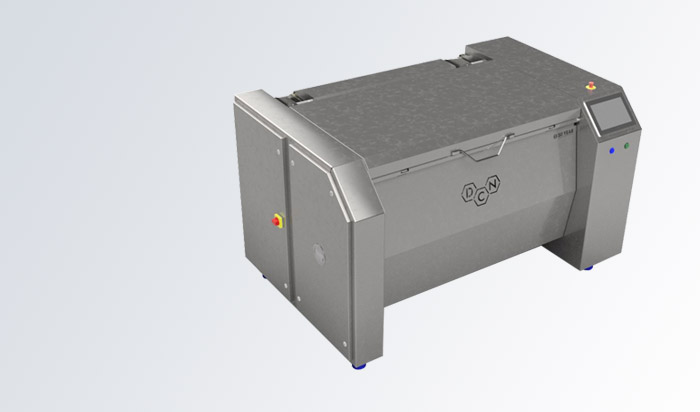

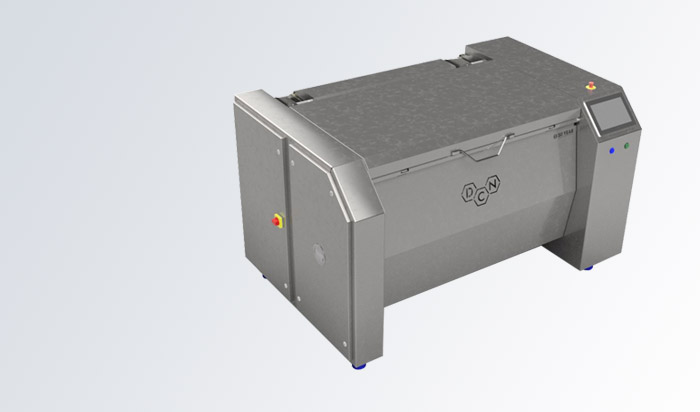

CT-5

Capacity: 551 lbs

Features: Fully automatic operation, power failure memory retention

CT-5E

Capacity: 551 lbs

Features: Electric heating

CT-10

Capacity: 950 lbs

CT-10E

Capacity: 950 lbs

Features: Electric heating

CT-20 Steam

Capacity: 1,900 lbs

Features: Steam heating

CT-20 Thermal Oil

Capacity: 1,900 lbs

Features: Thermal oil heating

Industrial & Commercial Sous Vide Cook Tanks by DC Norris North America

Sous vide is a cooking technique that involves cooking food under vacuum in airtight plastic pouches which are submerged in a cook tank/ water bath. Products are slow-cooked in the cook tank which is held at a precisely controlled low temperature ensuring foods are cooked evenly and to perfection every time. DC Norris North America offers sous vide cook tanks with capacities of up to 1,764 pounds, allowing large-scale industrial food producers to use this cooking method efficiently.

Request a Future Appointment

Industrial Sous Vide Equipment Delivers Perfect Results Every Time

The sous vide method of cooking eliminates guesswork and allows industrial producers to cook foods with incomparable taste and texture; perfectly cooked steak, tender chicken breasts, and ribs with the meat falling off the bone. With industrial sous vide, products can also be cooked in a sauce or marinade giving food manufacturers additional recipe choices. Slow-cooking foods at a low temperature through the industrial sous vide process improves texture, intensifies the flavors, and preserves the nutritional quality of the foods being prepared. Times and temperatures are rigidly controlled so producers can be sure that the results will be the same every time and easily replicable. Products can even be left to cook unattended overnight with guaranteed results.

Sous vide food preparation is used worldwide by professional chefs and is gaining popularity within the food processing industry as its advantages are being recognized.

Industrial Sous Vide Equipment for Food Manufacturers

The Cook Tank forms part of the DC Norris North America Cook-Chill system; designed to slow cook vacuum packaged meat, poultry, and prepared foods in a circulating hot water bath – industrial sous vide style. Slow cooking at lower temperatures in sealed plastic casings radically reduces meat shrinkage, while retaining more meat juices, and enhancing natural flavors and tenderness. Sous vide processing is used in the food industry to extend the shelf life of food products.

Sous vide is French for “under vacuum” and this method of food preparation is gaining popularity as more chefs recognize the advantages of the process. Foods are vacuum-sealed in plastic pouches, then cooked using precisely controlled heating. Temperatures are lower and cooking times are longer. The result is a dish that retains all of the moisture, nutrients, and flavors of the ingredients and is evenly cooked throughout.

DC Norris North America offers two types of cook tanks; a standard model for cooking only and the CTTC which is a dual-purpose machine. Throughout the day it is used in the Tumble Chiller mode for cooling pumpable foods such as soups and sauces. Filled casings are circulated in chilled water which reduces the temperature of cooked food to below 40 °F (4 °C) in under an hour. At night it can be programmed to Cook Tank mode which slow cooks vacuum packaged meats, poultry, and prepared foods in a circulating hot water bath − sous vide style.

Extended Shelf Life & Other Industrial Sous Vide Cooking Benefits

Foods cooked sous vide have an average shelf life of 60 days.

Sous vide virtually eliminates the potential for human error and inconsistent quality in the finished product.

The industrial sous vide method of cooking maximizes yields, particularly among foods traditionally prepared through roasting or similar processes that yield losses of up to 40 percent.

Sous vide cooking reduces the need for preservatives and additives.

Other methods of preparation require the use of additional ingredients and spices to tenderize meats. The sous vide process naturally tenderizes meats.

Sous vide can not only be largely unmonitored by human labor, it can also be cooked, chilled, stored, and rethermalized in the same package (for specific applications) allowing food producers to recognize substantial cost savings.

Sous vide allows prepared and cooked foods to be easily and safely transported great distances without compromising quality.

The sous vide method provides a biological barrier in its packaging, preventing many opportunities for contamination during cooking, cooling, and distribution.

The portion controlled packaging allows operations to control material costs.

The technique naturally intensifies flavors which allows for lower recipe ingredient costs.

Sous vide, without question, rose to today’s popularity for one main reason: it’s a foolproof way to deliver food products of consistently high quality. Today’s customer demands quality, nutrition, variety, and convenience. Sous vide allows global food producers to answer that demand.