Cooling

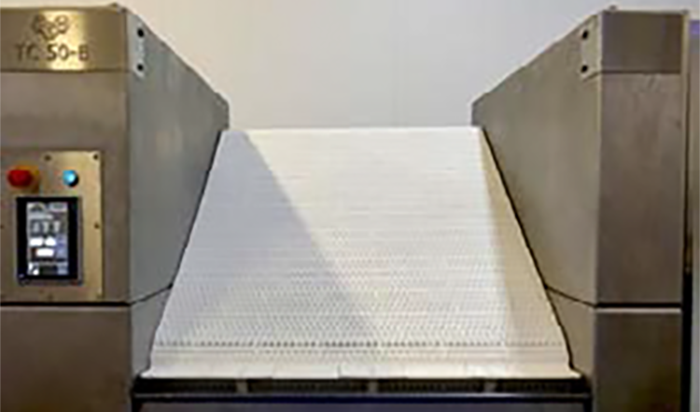

Industrial Cooling Equipment & Systems

DC Norris North America’s industrial cooling equipment and systems offer process innovation and excellence, retaining product quality while also keeping batch times to a minimum.

Our team has over 50 years of food processing experience and a wealth of recipe knowledge; they can assist you with both the processing solution and further development of your product.

Our cooling equipment portfolio provides three different cooling methods depending on the type of product and process requirements.

Industrial & Commercial Cooling Solutions by Category

Our Featured Cooling Equipment Brands