Sous Vide

The Sous Vide Method of Cooking

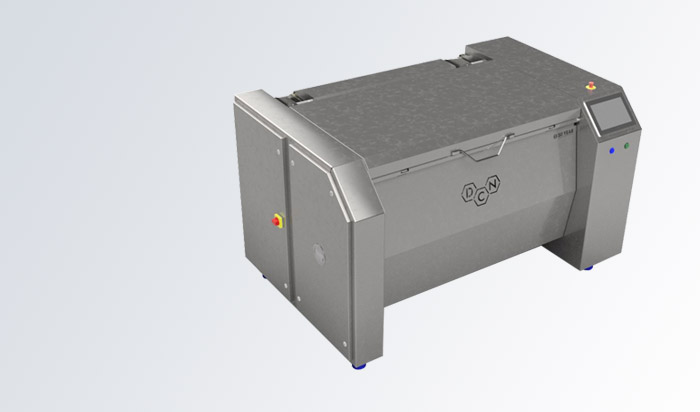

DC Norris North America supplies a range of equipment designed to empower fully automated sous vide cooking at both commercial and industrial scales.

Sous vide is a method of cooking food under vacuum in a water bath at a very precise, low, temperature. This method is often used by professional chefs but has also gained widespread adoption by both industrial and commercial food manufacturers.

There are several advantages to using sous vide for industrial food manufacturing. First, it is a very precise method of cooking. This means that food can be cooked to the exact desired temperature, which is important for ensuring food safety. Second, sous vide cooking is very gentle on food. This means that food retains its moisture and nutrients, which leads to a higher quality product. Third, sous vide cooking is very efficient. Food can be cooked in large batches, even unattended, which saves on labor input and cost.

For food producers using centralized production kitchens, sous vide cooking’s precision creates desirable consistency. While commonly regarded as a cooking method for animal proteins, sous vice can be used to cook a wide variety of foods including premium wet pet food, vegetables, and sushi rice.

Here are some additional benefits of using sous vide cooking in industrial food processing plants and commercial cooking:

- Sous vide cooking can help to improve food safety by killing harmful bacteria.

- Sous vide cooking can help to improve the taste and texture of food.

- Sous vide cooking can help to reduce labor costs by automating the cooking process.

- Sous vide cooking can help to improve the consistency of food quality.

- Sous vide cooking can help to reduce food waste by making it easier to cook food in small batches.