Recipe Control

Recipe Management Software

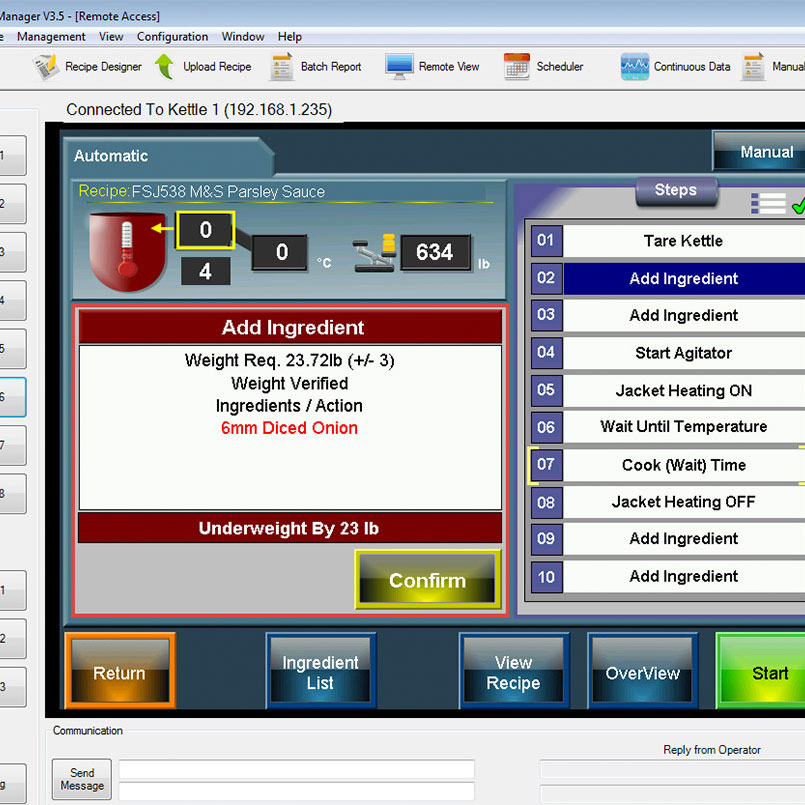

Our Recipe Manager software package is simple to use and offers a flexible method of controlling a recipe-driven production process. Working closely with our customers to understand and identify what they require; we have developed the very best recipe management software system on the market.

The user-friendly Recipe Manager system allows commercial food producers to create ingredient listings, step–by–step procedural recipes, and user access security with all recipes stored in a relational database. The system maintains full records of kettle yields, allowing bar code identification from preparation through to packaging, and ensures all HACCP controls are met.

Recipe Manager Features

- Forces the operator to follow a logical sequence of events

- Temperatures, cook times, and motor speeds are automatically controlled by the recipe

- Visual display of plant layout and fault notification

- Records all weights, temperatures, sequences, deviations, and errors.

- Creates batch reports in text and graph formats

- Piped additions are batched in automatically and verified by either load cell or flow meter

- Touch Screen for operator use

- DCN Software Engineers can log-in remotely utilizing a local broadband connection and make any updates to your system or assist with queries

- Displays machine operator HMI screens in real-time (remote view)

- Data can be exported to the most popular formats such as Xls, Pdf, and HTML

We also offer a ‘Lite’ Version of Recipe Manager

- A simplified version of ‘Full’ Recipe Manager

- Recipes created on HMI screen only

- Suitable for standalone kettles with limited recipes

Food Processing Software: Virtual Chart Recorder

The DC Norris Virtual Chart Recorder software has been designed to record real-time data produced by your processing system. This allows industrial food manufacturers to log information relating to temperature changes in any cooking and/or cooling process.

The Virtual Chart Recorder software stores this data in a database that remains ready for our clients to quickly produce historic cycle process records and trends.

Virtual Chart Recorder Features

- Can record data from a variety of different machines – not just DC Norris equipment

- All data stored in a Relational database

- Records recipe and operator names

- Records Date, batch time (start, finish, total)

- Reports generated and printed against selected database records

- Data can be exported to the most popular formats such as Xls, Pdf, and HTML Displays machine operator HMI screens in real-time (remote view)