WHAT IS THE COOK CHILL METHOD?

The cook chill method is a food preparation process that involves the rapid chilling of cooked food. The food product is cooked in large batches, then (often) dispensed into smaller bags for ease of storage and transportation. Both commercial and small-batch kitchens can benefit from the cook chill method to quickly reheat and serve many high-use products such as soups, sauces, chilis, or pasta dishes. The cook chill method works equally well for many other food types and follows the following steps for perfect cooking, storage, and use.

1. Cook

Food is frequently put into specially designed steam jacketed or electric kettles to cook.

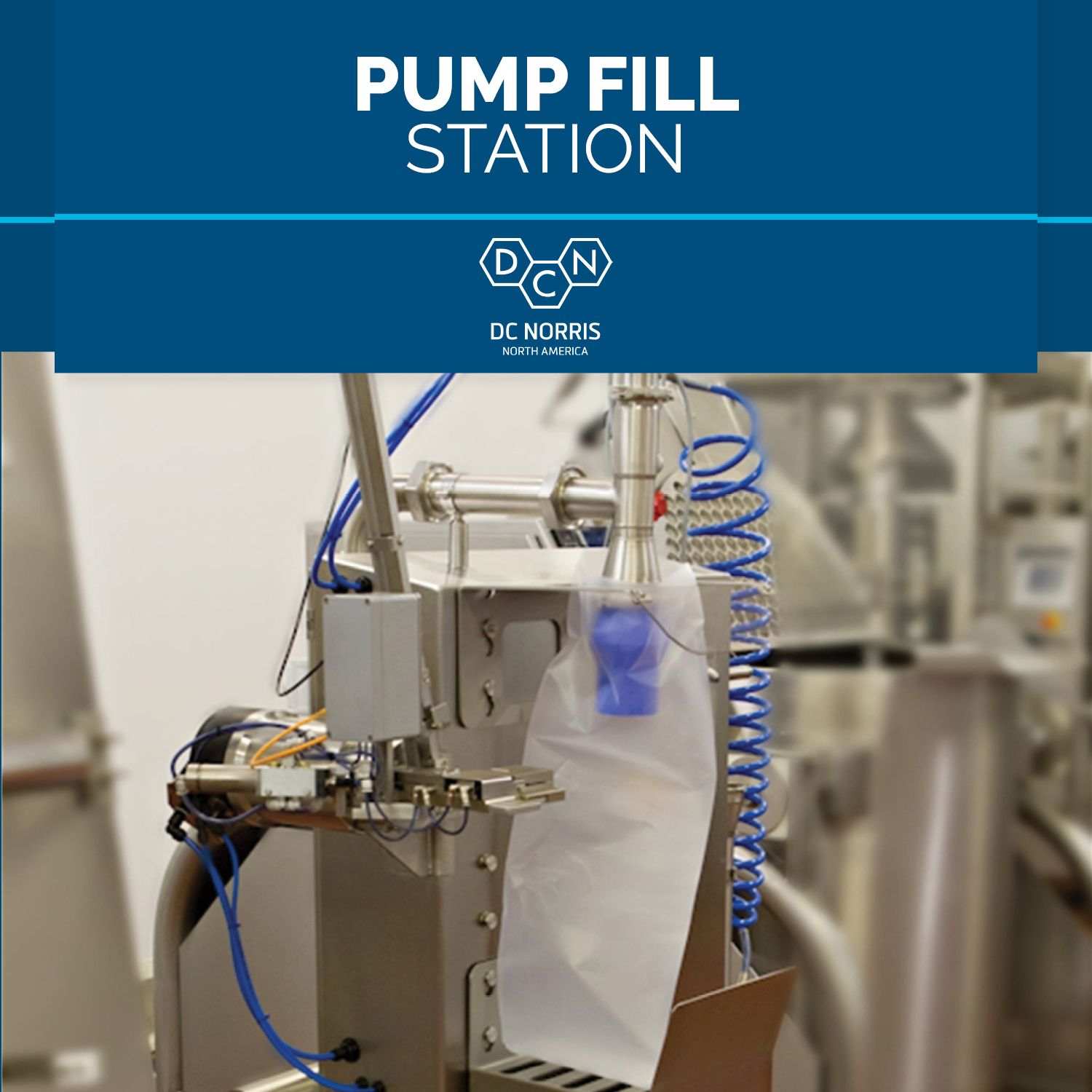

2. Bag Fill

The finished products are measured, sealed, and labeled through a pump fill station. Products like DC Norris’s Model 400 Heat Seal Pump Fill Station seal bags for extended shelf life and offer a process that involves high safety standards and minimal operator handling.

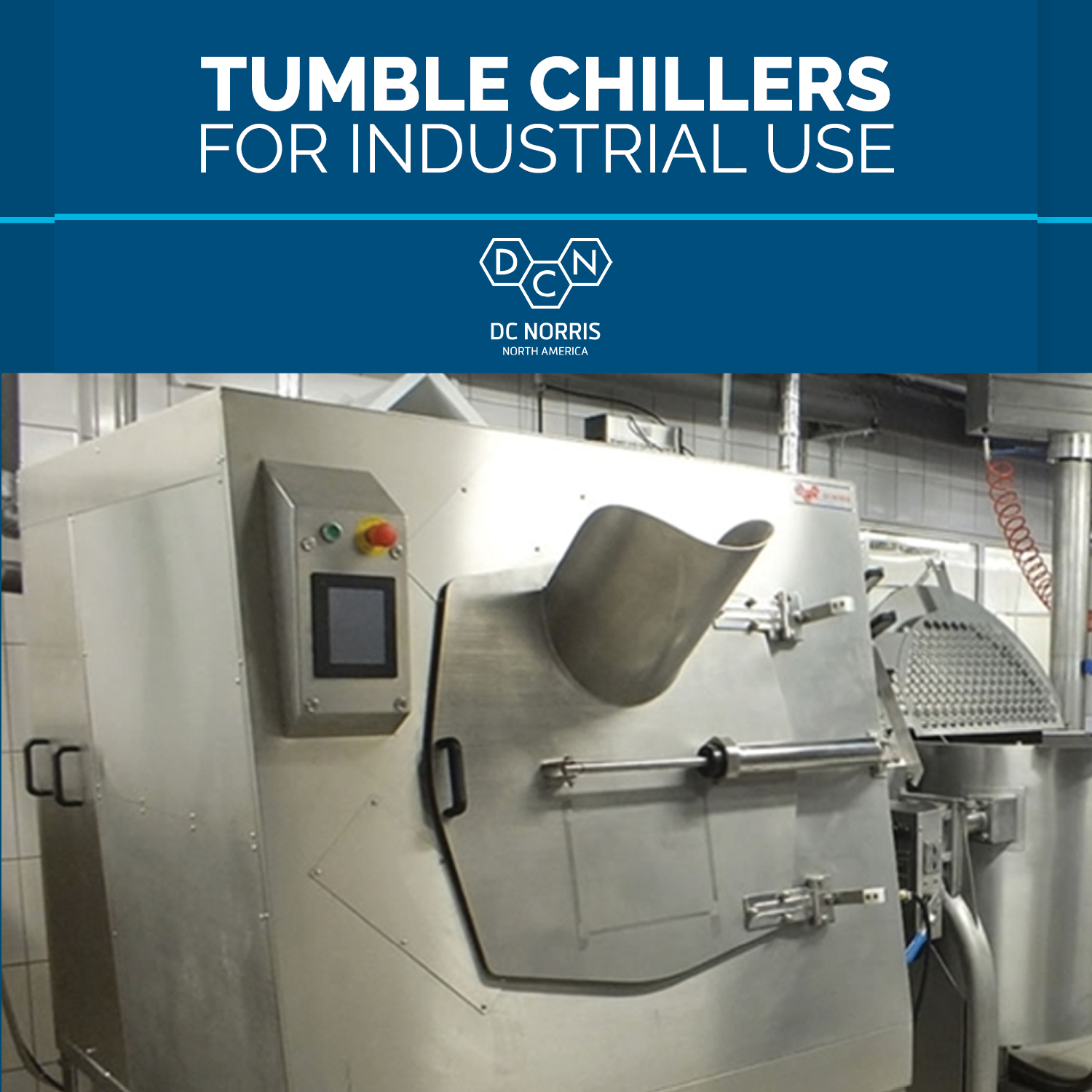

3. Chill

Once sealed, the bags are immediately placed in a tumble chiller or belt tumble chiller, which rotates the food, gently tumbling the bags and massaging the product to ensure cooling and minimal product damage.

4. Store/Ship

The cooled bags are taken from the chiller to be frozen, stored locally, or shipped out. The durable bags stack easily and help minimize the need for large storage spaces and shipping costs.

5. Reheat

When the product arrives at its final destination, it can be reheated in a hot water bath, a steamer, or placed directly into a pot or pan.

6. Serve

The final food product delivers a quality, freshly cooked taste!

WHY YOU SHOULD USE THE COOK CHILL METHOD

The demand for fast, ready-to-eat meals has put pressure on the food industry to rise and meet this challenge. One solution is to batch prepare food using the cook chill method. You can use this method to preserve fresh, in-season ingredients and save time and labor preparing batches of the same menu item. The cook chill method is a cost-effective way to provide mass quality of foods while reducing overhead costs, and it has a multitude of additional benefits as well, such as:

- Using sealed bags keeps out contaminants, which provides less risk of cross-contamination or exposed food products.

- The consistency of cooking food in larger batches ensures the same final product, no matter who cooks.

- Large batch products require less effort for more results, and it will improve overall kitchen efficiency.

- Depending on the type of food, bagged and sealed food can last several days or even weeks in controlled cold storage, extending product shelf life.

ABOUT THE DC NORRIS COOK CHILL SYSTEM

The DC Norris Cook Chill System has become an industry standard with food companies around the world using the ground-breaking cook chill technology. The food industry can create high-quality meals with a safe extended shelf life that retains the taste, texture, and aroma of freshly prepared ingredients. Using the cook chill method with our fleet of cooking products like our Steam Jacketed Kettles, Pump Fill Stations and Tumble Chillers provides industrial and commercial food producers the convenience of delicious batch cooked foods that are safe and cost-effective.

Interested in learning more about the equipment discussed in this article? Choose any category below.